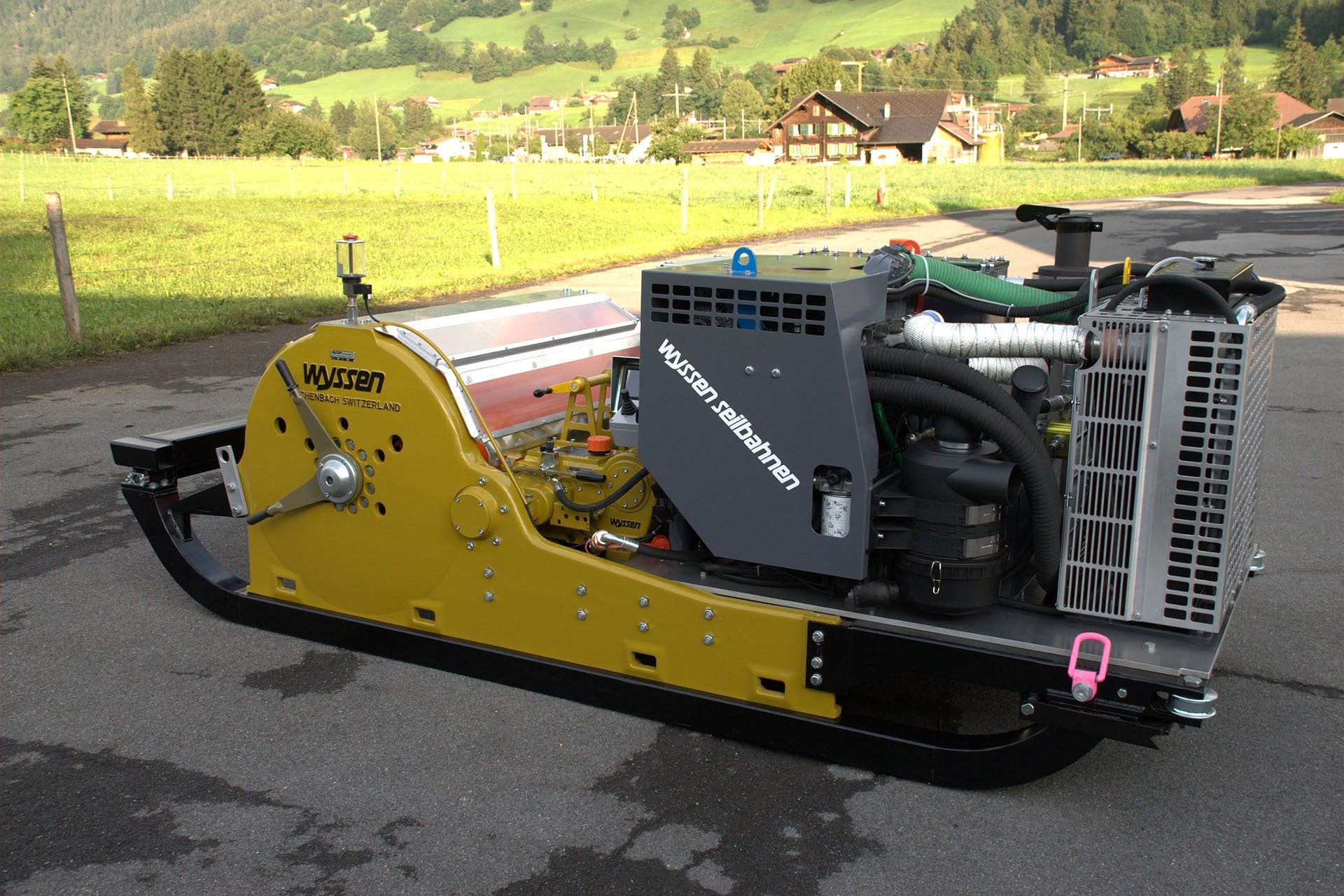

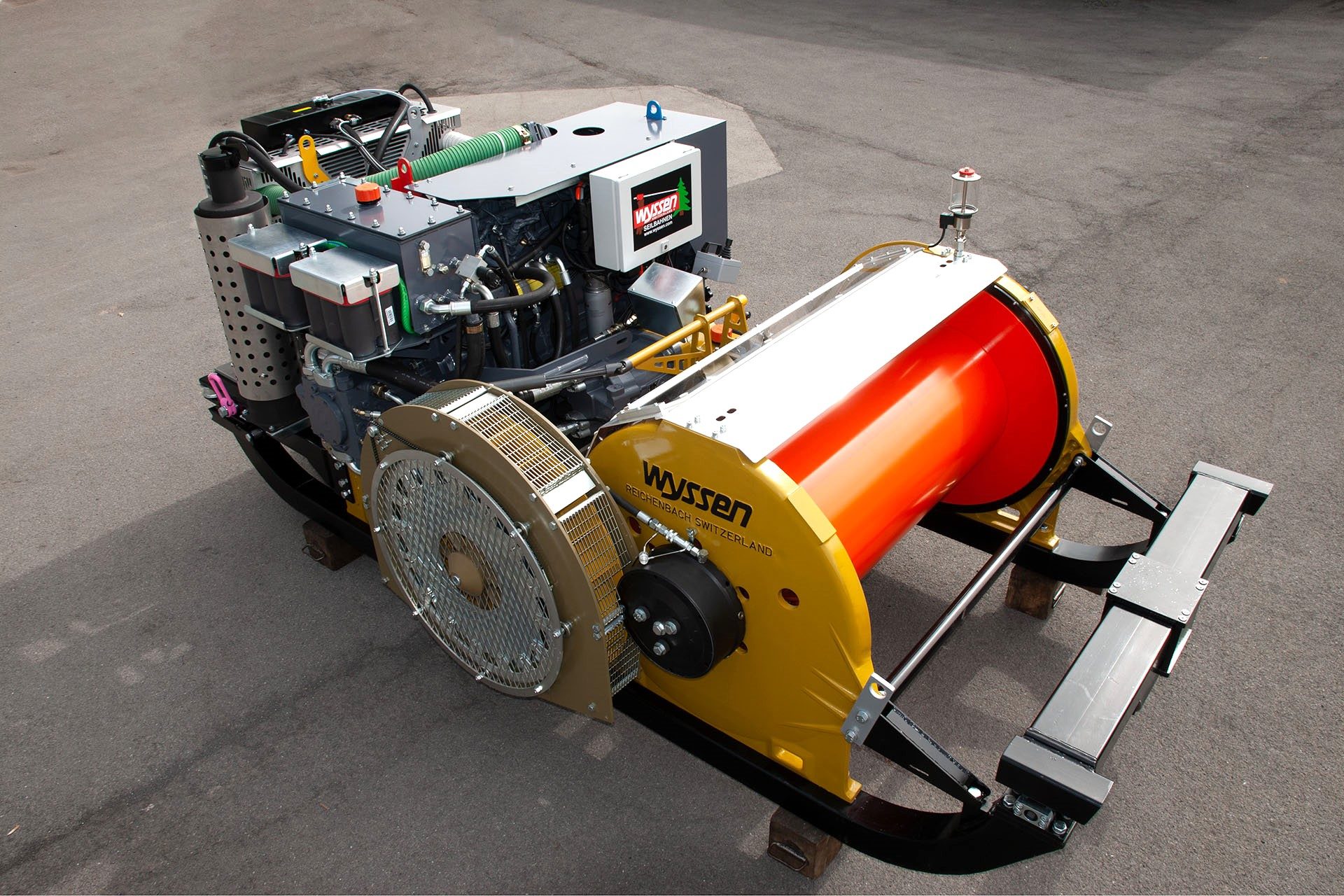

Cable Winch W-90

The cable winch for high loads capacities

Brake systems

Holding brake:

- Shoe brake mounted directly in the drum

Driving brake optional:

- Air brake

- Eddy current brake

- Hydraulic safety brake (dead man’s switch brake)

Power transmission

- Hydrostatic drive, continuously adjustable

Motors

- 4 cylinder turbo diesel 129 kW / 175 HP charge air cooled

- 6 cylinder turbo diesel 194 kW / 263 HP charge air cooled

- Electric motor

Set up and function

The W-90 cable winch is primarily used as a drive unit for cableways on building sites where high tractive forces are required. When fitted with a grooved pulley or a capstan ring, the cable winch can be used as a circular drive wheel for a material cableway. The grooved pulley or the capstan ring can be easily fitted or removed. The W-90 cable winch is fitted with a charge-air cooled 4 cylinder Deutz turbo-diesel motor with 129 kW or for higher performance, the 6 cylinder Deutz turbo-diesel motor with 194 kW, also charge-air cooled. The cable winch is ideally suitable for our MSK 2 and MSK 3 motorised skyline cranes and also for our carriages, with or without trailers, for heavy load capacities. Due to the large cable drum the W-90 has a significantly larger cable capacity than the W-30 and the W-40. The W-90 cable winches are equipped with the same modern control system for automatic operation on the W-40/175. Furthermore the separate diesel connection on the cable winch allows it to be connected to an external diesel tank. The W-90 cable winch is also modular in construction, as are all Wyssen cable winches, so that it can be adapted to the individual requirements of each customer.

Options

The cable winch W-90 is available with the following options and accessories:

- wide sled runners

- electronic distance indicator

- Splash protector

- Protective cover

- Luggage rack

- Suspension gear

- Unimat drive (circulation with feed roller and swiveling deflection rollers)

- Circular drive wheel with Becorit lining or parabolic pulley

- Free-wheel for air brake

- Cable guide roller

- Overfill safety device

- Slack cable safety device

- Remote control

- Radio with automatic target

- Radio control with automatic guidance system

- Transport trailer

- Oil-cooled gearbox and filtration

Technical data

| Main Dimensions Cable Winch-90 | W-90/175 | W-90/263 |

|---|---|---|

| Length | 3’450 mm | |

| Width | 1’550 mm | |

| Height | 1’360 mm | |

| Drum-ø | 484 mm | |

| Drum width | 1’152 mm | 1’138 mm |

| Total weight | 2’770 kg | 2’900 kg |

| Cable Drum Capacity | W-90/175 | W-90/263 |

| Cable-ø 9.5 mm | 3’830 m | |

| Cable-ø 10.0 mm | 3’320 m | |

| Cable-ø 10.5 mm | 3’200 m | |

| Cable-ø 11.0 mm | 2’830 m | |

| Cable-ø 12.0 mm | 2’560 m | |

| Seil-ø 13.0 mm | 2’050 m | |

| Cable-ø 14.0 mm | 1’730 m | |

| Cable-ø 15.0 mm | 1’680 m | |

| Cable-ø 16.0 mm | 1’390 m | |

| Cable-ø 18.0 mm | 1’110 m | |

| Tractive Forces and Speeds W-90/175 and W-90/263 | Drum Empty | Drum Half-Full | Drum Full |

|---|---|---|---|

| Gearbox model A | 9.82 m/s 4’866 kg | 12.77 m/s 3’953 kg | 15.72 m/s 3’041 kg |

| Gearbox model B | 8.64 m/s 5’526 kg | 11.24 m/s 4’491 kg | 13.83 m/s 3’454 kg |

| Gearbox model C | 8.20 m/s 5’830 kg | 10.65 m/s 4’736 kg | 13.14 m/s 3’643 kg |

| Gearbox model D | 7.22 m/s 6’622 kg | 9.38 m/s 5’380 kg | 11.54 m/s 4’139 kg |

| Gearbox model E | 6.35 m/s 7’524 kg | 8.26 m/s 6’113 kg | 10.16 m/s 4’702 kg |

| Gearbox model F | 6.02 m/s 7’935 kg | 7.82 m/s 6’423 kg | 9.63 m/s 4’910 kg |

| Gearbox model G (standard model) | 5.30 m/s 9'015 kg | 6.89 m/s 7'324 kg | 8.48 m/s 5'633 kg |

Wyssen Control System FSI 2007

The self-developed FSI control system is installed in the W-90 cable winch. The control is also mounted in the following machines: Carriage Slackpuller, Carriage Universal, Motorised Skyline Crane, Cable Winch W-30 and in the Cable Winch W-40.

Advantages

- operable with radio

- can be adapted for the existing radio remote control on the mobile cable crane

- automatically switches off when not in use

- clamping with a radio signal during the journey via set speed no longer possible

- Automatic emergency stop if the programmed speed limit is exceeded

- Display for setting the parameters

- All parameters can be individually adjusted (speed, clamping and delay times)

- Battery status display

- CAN-Bus interface

- Integrated 3D inclination sensor

- Resistant against moisture, vibration and impact due to completely enclosed electronics

- Plug is secured with screws

- Software updates with improvements and upgrading is possible at any time