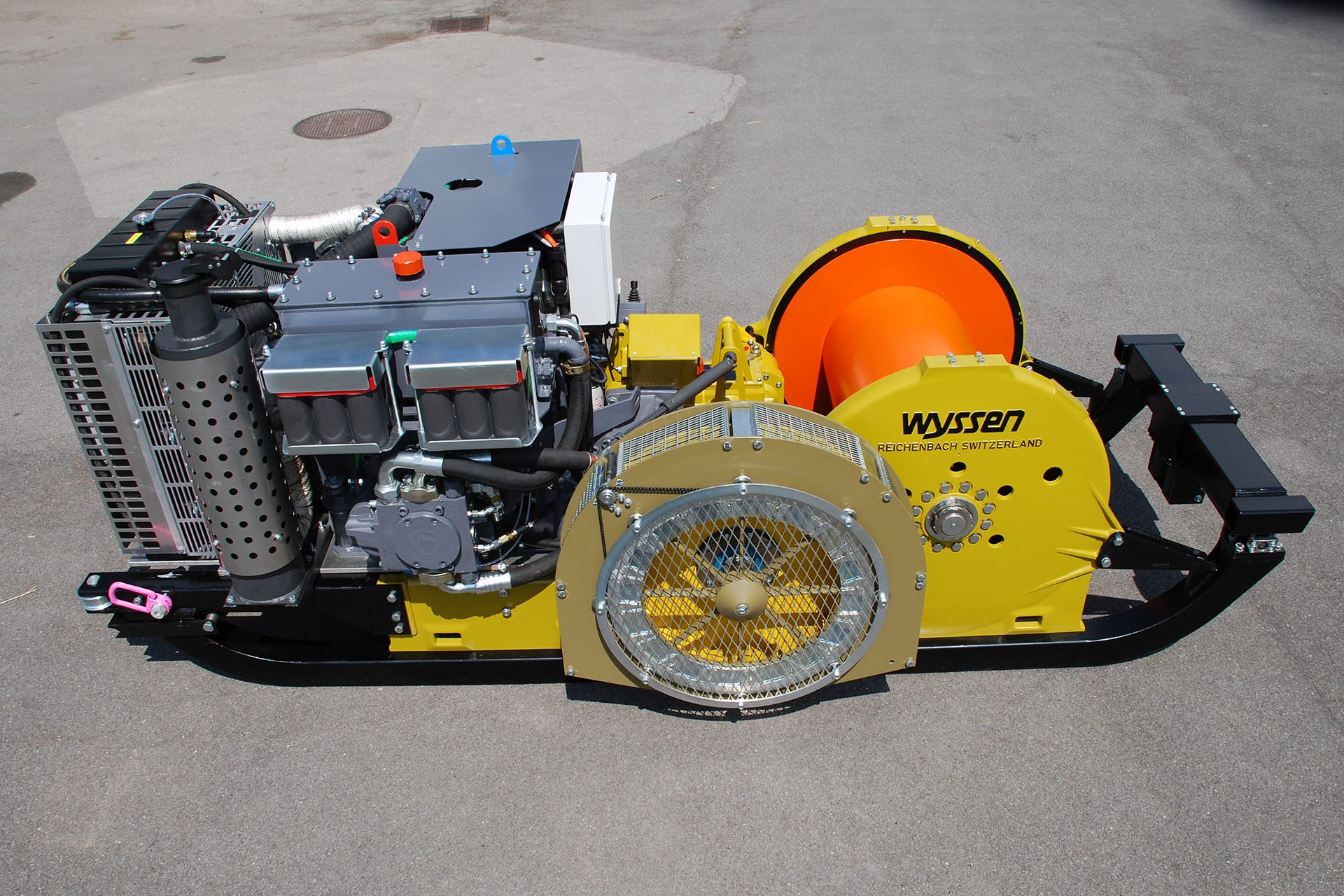

Cable Winch W-40

A power-house for the forestry and construction industries with a large cable capacity

Brake systems

Main brake:

- Internal expanding shoe brake in drum

Driving brake optional:

- Air brake (Mars or Jupiter)

- Eddy current brake possible

Safety brake

- Hydraulic safety brake (dead man’s switch brake)

Power transmission

- Hydrostatic drive, continuously adjustable

- or mech. 6-speed gearbox (older machines or regions where hydraulics are not common)

- With fluid turbo coupling (with mechanical 6 speed gearbox)

Motors

- 4-cylinder Hatz turbodiesel 55kW/74HP (water-cooled with DPF for EU emission stage V)

- 4-cylinder Deutz turbodiesel 129kW/175HP inter-cooled (water-cooled, EU IIIA/US Tier 3 emissions standard, no longer available for CH/EU for new machines)

- Electric motor 37kW/50 PS

Set up and function

The Wyssen W-40 cable winch is practically identical to the W-30. The difference is that the W-40 has higher side-walls, which allows a larger cable drum to be fitted with a higher cable holding capacity. The cable winch is mainly used like the W-30 as a driving unit in the wood and forest industries as well as in the construction industry. It is ideally suitable for long-distance cableways together with our carriage HY-4 or slackpuller carriage and our MSK2 motorised skyline crane up to load capacities of 40 kN/4 t. With the grooved sheave equipped, the W-40 cable winch can also be used as a endless-rope drive for material cableways.

The latest engine is the Hatz turbodiesel with 55kW/74PS. It fulfills the exhaust emission stage V required in the CH/EU area. It is equipped with a diesel particulate filter, which prevents clogging with an automatic regeneration function. The engine installed in our vehicle has an output of 55 kW, which is the limit before an additional complex exhaust gas aftertreatment system (AdBlue) comes mandatory. The entire drive train is electronically controlled, enabling semi-automatic operation thanks to our specially developed control system with display. Supports and end points can be easily entered so that the cable crane automatically slows down at the supports and stops at the end points. The cable winch, which weighs approx. 1750 kg (depending on equipment/options), can be quickly and easily separated into two parts (chassis and motor assembly), which means that the cable winch can also be transported with smaller helicopters. The W-40 is also available with an electric drive and our modern control system. On request, the cable winch can also be controlled by radio, depending on the application. If more power is required, the cable winch is also available with more powerful engines, depending on exhaust emission regulations, enabling heavy loads to be transported uphill at high speed. The W-40 cable winch is modular in construction, as are all Wyssen cable winches, so that it can be adapted to the individual requirements of each customer.

Options

The Wyssen cable winch W-40 is available with the following options and accessories:

- wide sled runners

- electronic distance indicator

- Splash protector

- Protective cover

- Unimat drive (circulation with feed roller and swiveling deflection rollers)

- Circular drive wheel with Becorit lining or parabolic pulley

- Free-wheel for air brake

- Cable guide roller

- Overfill safety device

- Adjustable front-rollers as cable guides (steering device when self-ropping in terrain)

- Anti-sliding brackets (prevents sliding backwards in steep terrain)

- Additional rope winding drum instead of air-brake (interchangeable equipment)

- Remote control

- Radio with automatic target

- External battery charge socket

- Battery kill-switch and ignition key

- External fueling connector

- Hoisting equipment for winch

- Exhaust extension

- Drip feed lubricator

- Radio control with automatic guidance system

- Transport trailer

- Oil-cooled gearbox and filtration

Technical data

| Main Dimensions Cable Winch-40 | W-40/74 | ||

|---|---|---|---|

| Length | 2’990 mm | ||

| Width | 1’335 mm | ||

| Height | 1’360 mm | ||

| Drum-ø | 476 mm | ||

| Drum width | 832 mm | ||

| Total weight | 1’750 kg | ||

| Cable Drum Capacity | W-40/74 | ||

|---|---|---|---|

| Cable-ø 9.0 mm | 3’250 m | ||

| Cable-ø 9.5 mm | 2’740 m | ||

| Cable-ø 10.0 mm | 2’580 m | ||

| Cable-ø 10.5 mm | 2’300 m | ||

| Cable-ø 11.0 mm | 2’030 m | ||

| Cable-ø 12.0 mm | 1’850 m | ||

| Seil-ø 13.0 mm | 1’480 m | ||

| Cable-ø 14.0 mm | 1’250 m | ||

| Cable-ø 15.0 mm | 1’080 m | ||

| Cable-ø 16.0 mm | 1’000 m | ||

| Tractive Forces and Speeds W-40 | Drum Empty | Drum Half-Full | Drum Full |

|---|---|---|---|

| Gearbox model A | 8.19 m/s 3’544 kg | 10.64 m/s 2’880 kg | 13.10 m/s 2’215 kg |

| Gearbox model B | 7.20 m/s 4’025 kg | 9.36 m/s 3’270 kg | 11.53 m/s 2’515 kg |

| Gearbox model C | 6.83 m/s 4’245 kg | 8.88 m/s 3’449 kg | 10.93 m/s 2’653 kg |

| Gearbox model D | 6.02 m/s 4’823 kg | 7.82 m/s 3’918 kg | 9.62 m/s 3’014 kg |

| Gearbox model E (standard model) | 5.30m/s 5’478 kg | 6.84 m/s 4'450 kg | 8.47 m/s 3'423 kg |

| Gearbox model F | 5.02 m/s 5’780 kg | 6.53 m/s 4’696 kg | 8.03 m/s 3’612 kg |

| Gearbox model G | 5.08 m/s 5’522 kg | 6.10 m/s 4’733 kg | 7.12 m/s 3’944 kg |

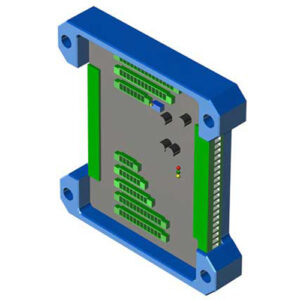

Wyssen Control System FSI 2007

The self-developed control FSI sytem is installed in the cable winch W-40. The control is also mounted in the following machines: Carriage Slackpuller, Carriage Universal, Motorised Skyline crane, Cable Winch W-30 and in the Cable Winch W-90.

Advantages

- operable with radio

- can be adapted for the existing radio remote control on the mobile cable crane

- automatically switches off when not in use

- clamping with a radio signal during the journey via set speed no longer possible

- Automatic emergency stop if the programmed speed limit is exceeded

- Display for setting the parameters

- All parameters can be individually adjusted (speed, clamping and delay times)

- Battery status display

- CAN-Bus interface

- Integrated 3D inclination sensor

- Resistant against moisture, vibration and impact due to completely enclosed electronics

- Plug is secured with screws

- Software updates with improvements and upgrading is possible at any time