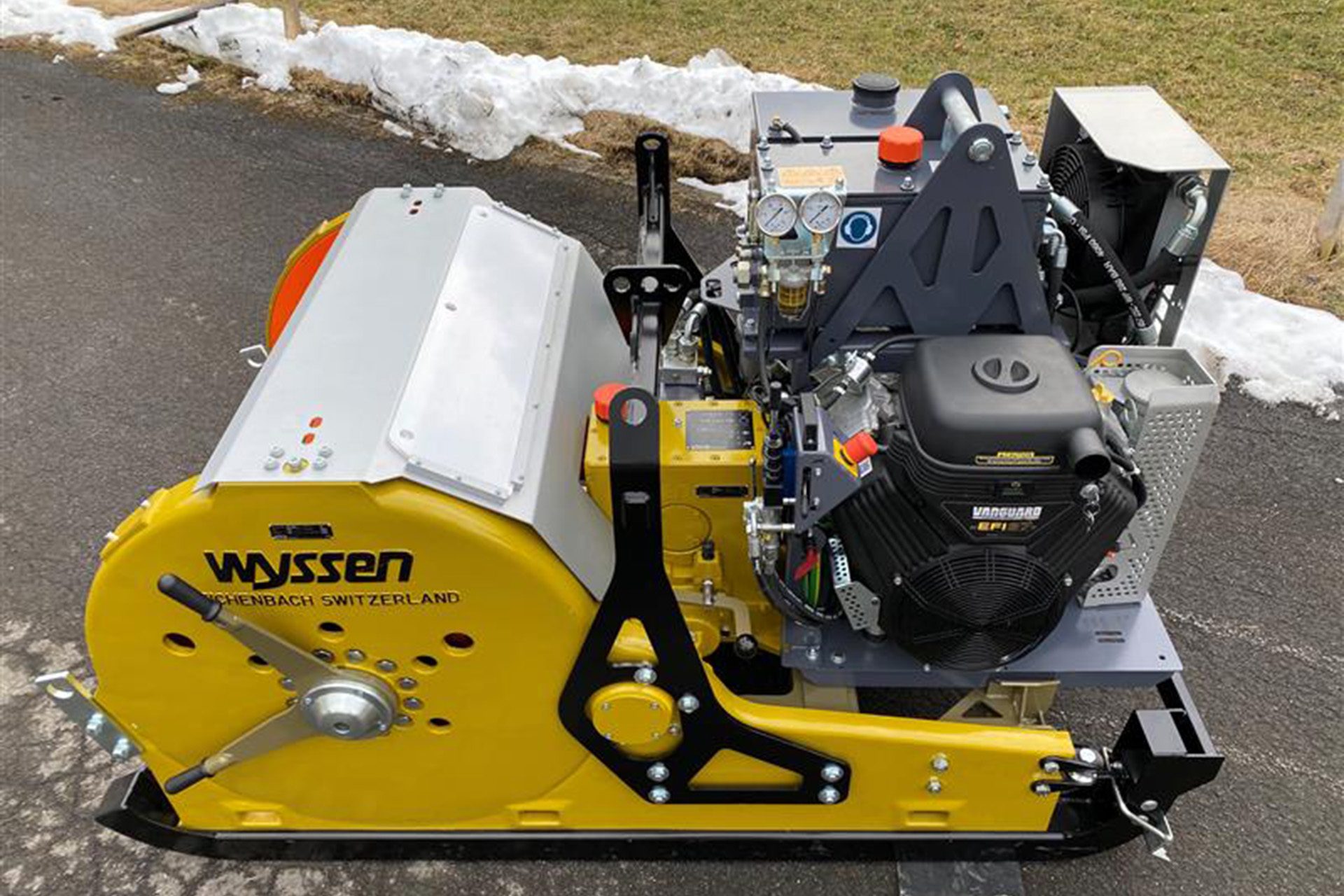

Cable Winch W-24

The compact yet powerful cable winch for assembly work

Brake systems

Main brake:

- Internal expanding shoe brake in drum (hand brake)

Driving brake optional:

- Air brake (Mars or Jupiter)

- Eddy current brake

Safety brake:

- Hydraulic safety brake (dead man’s switch brake)

Power transmission

- Hydrostatic forward and reverse stepless with additional mechanical 2-speed transmission (high speed, slow speed / high speed, less tractive force)

- Mooring system (Mooring mode can be switched on, constant tension)

Motors

- 2 cyl. Briggs Stratton Vanguard EFI petrol engine, 37hp/27.6kW with 3600U/min

Set up and function

The W-24 Cable winch has been developed as the successor to the tried and tested compact W-20 together with the W-40 drum size that reduces cable wear. The main features are the compact construction and the high tractive forces, specially designed for all types of assembly work. The cable winch is driven by a modern Briggs Stratton Vanguard EFI petrol engine, which complies with the current Stage 5 (Stage V) emissions standard. This engine is approved for use on all European and Swiss construction sites. The W-24 Cable winch is also fitted with the necessary safety brake (hydraulic spring-powered brake/dead man’s brake).

The cable winch drum is driven continuously forwards and backwards with a hydrostatic drive. The additional 2-speed transmission allows the cable winch to be driven either with higher traction or at a faster speed. Optionally the W-24 cable winch also has a mooring system (constant tension), which can be connected at any time with a lever. The Mars and Jupiter air brakes as well as the eddy-current brake can be mounted on demand. The cable winch can easily and quickly be dismantled into 2 parts for transportation with a small helicopter.

Special guides on the sled ensure the motor is automatically aligned when set down, so that the units can be quickly and easily screwed together. The complete cable winch can also be lifted up with just one specially provided suspension point.

The very similar construction to the W-30 and W-40 cable winches permit any option such as distance indicators, Unimat drive, continuous drive, air brake, etc. (see options and accessories) to be used from these cable winches.

Options

The Wyssen W-24 cable winch is available with the following options and accessories:

- electronic distance indicator

- Splash protector

- Protective cover

- Luggage rack

- Suspension gear

- Unimat drive (circulation with feed roller and swiveling deflection rollers)

- Circular drive wheel with Becorit lining or parabolic pulley

- Free-wheel for air brake

- Cable guide roller

- Overfill safety device

- Slack cable safety device

- Adjustable front-rollers as cable guides (steering device when self-ropping in terrain)

- Anti-sliding brackets (prevents sliding backwards in steep terrain)

- Engine tachometer, hour meter and malfunction indicator

- External battery charge socket

- Battery kill-switch and ignition key

- External fueling connector

- Hoisting equipment for winch

- Exhaust extension

- Drip feed lubricator etc.

Technical data

| Tractive forces and Speeds W-24 | Drum Empty | Drum Half-Full | Drum Full |

|---|---|---|---|

| Power speed | 0.5 m/s 5'000 kg | 0.65 m/s 3'864 kg | 0.79 m/s 3'148 kg |

| Fast speed | 1.8 m/s 1’500 kg | 2.33 m/s 1'159 kg | 944 kg |

| Main dimension cable winch W-24 | Measures |

|---|---|

| Length | 2'075 mm |

| Width | 1’300 mm |

| Height | 1’315 mm |

| Drum-ø | 476 mm |

| Drum width | 832 mm |

| Total weight (complete / depending on version) | 1’230 kg |

| Weight of motor unit | 340 kg |

| Chassis weight | 940 kg |

| Cable Drum Capacity | Measures |

| Cable-ø 9.0 mm | 3'250 m |

| Cable-ø 9.5 mm | 2'740 m |

| Cable-ø 10.0 mm | 2'580 m |

| Cable-ø 10.5 mm | 2'300 m |

| Cable-ø 11.0 mm | 2'030 m |

| Cable-ø 12.0 mm | 1’850 m |

| Seil-ø 13.0 mm | 1'480 m |

| Cable-ø 14.0 mm | 1'250 m |

| Cable-ø 15.0 mm | 1'080 m |

| Cable-ø 16.0 mm | 1'000 m |