Carriage HY-4 / HY-7

The carriage for long-distance cableways.

Set up and function

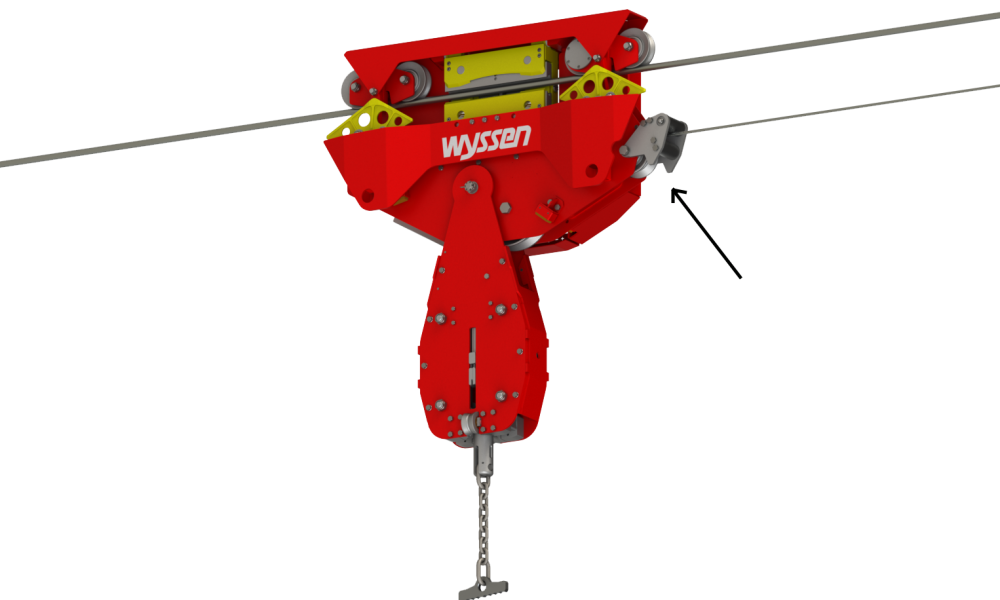

The HY-4 carriage is used principally as a long-distance cable crane in the forestry and construction industries. It has four distinguishing guide pulleys to conserve the skyline and for gentler transit over the supports. The load pendulum is available with or without a large-dimensioned mainline clamp. In both versions the load hook is incorporated into the pendulum and the mainline is relieved of the weight during the run, so that the mainline will not be damaged, even by the heaviest impacts of long timber loads during rapid descents. The suspended load is also protected against the cable twisting, so that damage to the steel wire cable is also prevented. Like the HY-2 type, the HY-4 carriage is also equipped with the Wyssen FSI carriage control system. It is operated using specially programmed buttons on the radio, as are all of our carriages. It can, however, be switched over at any time to the conventional timer switch, so that the system can be operated without remote radio control. In addition to the standard version, the HY-4 carriage can be fitted with various options, such as a motorised slackpuller, a trailer carriage with bar or a mainline clamp. The HY-7 carriage is technically identical to the HY-4 carriage and is mostly used in the construction industry. The difference is that the HY-7 is significantly larger and stronger and is designed for load capacities of up to 7 tonnes.

Carriage HY-4 / HY-7

Advantages

- Novel concept with very few moving parts

- Self-contained compact construction with moving parts on the inside

- Easy to service

- Minimum wear to mainline due to 4 large guide pulleys

- The large lifting pulley causes minimum wear to mainline

- Plenty of room for the simplified pulling-in of the mainline

- Smooth passage over the supports thanks to the 4 guide pulleys

- Passes over large and small Wyssen support saddles

- Complete construction made from high-grade steel

- Chrome-molybdenum steel safety guards prevent derailment from the skyline, allowing fast travel over the supports.

- Large swinging angle of pendulum

- Very low wear on the mainline thanks to the special clamping

- Cable safety brake standard

- Screwed construction, allowing the chassis to be dismantled into small replaceable parts

Load hooks for HY-4

1) normal hoisting hook

- cables up to ø 12 mm

- 18 kg

2a) normal choker spindle

- cables up to ø 12 mm

- 10 kg

2b) Alu choker spindle

- cables up to ø 12 mm

- 5 kg

3) large hoisting hook

- cables up to ø 16 mm

- 35 kg

Technical data

| Specifications | HY-4 | HY-7 |

|---|---|---|

| Length | 1’270 mm | 1’560 mm |

| Width | 280 mm | 390 mm |

| Height | 900 mm | 1’116 mm |

| Hydraulics | 100 bar | |

| Skyline-ø | 16 – 36 mm | up to max. 45 mm |

| Mainline-ø | 9 – 16 mm | up to max. 20 mm |

| Unladen weight | approx. 350 kg | approx. 630 kg (depending on model) |

| Load capacity | 4’000 kg | 7’000 kg |

Advantages of the remote radio control

- Precise clamping and release at the touch of a button

- Hook swings out by clamping during slow descent

- Does not have to be raised when clamping during slow uphill driving, even with load

- Hand-held radio serves at the same time as remote control

- Can be retrofitted to any HY-4

- Electronic time release can be activated if the wireless communication is interrupted

- Protected against clamping when travelling too fast

- Protected against clamping if the battery is discharged

Options for HY-4 carriages

In addition to the standard version, the HY-4 carriage can be fitted with various options, including mainline clamp, motorised slackpuller, or a trailer carriage with transport bar. The options motorised slackpuller and trailer carriage with transport bar can be quickly coupled and uncoupled. The motorised slackpuller spools out the mainline, so that even for flat and very long cableways the hook can be lowered without an additional weight. The work of the attaching operator is thus made considerably easier. The mainline between the carriage and the winch is always under tension so that perfect winding onto the cable drum is ensured. The motor and spooling out are also operated by the buttons on the radio. If the motorised slackpuller is not required, such as e.g. for steep cableways (gravitational operation), it can be quickly and easily uncoupled and normal operation resumed with the carriage alone. The trailer carriage with transport bar is used mainly in the construction industry for lifting, transporting, lowering and moving of long and heavy parts such as e.g. pressure pipe and gas pipelines, or also for transporting concrete and gravel. The transport bar also prevents the load twisting and twisting of the mainline is also not possible even if the lowered load is left hanging for some time. The retracted load is locked in both the carriage and in the trailer carriage, so that the load is doubly protected against falling during the run.

HY-4Z Mainline Clamp

The mainline clamp in the pendulum allowed repeated movements for loads lowered at any height. It is operated with the portable radio equipment and can be used with both the motorised slackpuller and the trailer carriage with transport bar. The especially large mainline clamps in the load pendulum reduce wear on the mainline and in addition the load hook is locked in the pendulum when the hook is completely retracted. Thus the mainline will not be damaged, even by the heaviest impacts of long timber loads during rapid descents.

Advantages

- Clamp integrated into the load pendulum

- with the hook fully withdrawn in the carriage, the clamp is openand the load is docked in the pincers of the pendulum

- can be retrofitted to any HY-4

| HY-4 Specifications with mainline clamp | Description |

|---|---|

| Length | 1’270 mm |

| Width | 280 mm |

| Height | 1'010 mm |

| Hydraulics | 100 bar |

| Skyline-ø | 16 – 36 mm |

| Mainline-ø | 9 – 16 mm |

| Unladen weight | approx. 428 kg |

| Load capacity | 4’000 kg |

HY-4M Motorised Slackpuller

Advantages

- Hook comes out on its own even for horizontal runways

- The spooling procedure starts automatically when needed

- Tractive force adjustable from 50 – 400 kg

- Mainline is always under tension up to the winch

| HY-4M Specifications with motorised Slackpuller | Description |

|---|---|

| Length | 2’680 mm |

| Width | 535 mm |

| Height of pendulum normally | 900 mm |

| Height of pendulum mainline clamp | 1'010 mm |

| Hydraulics | 100 bar |

| Skyline-ø | 16 – 36 mm |

| Mainline-ø | 9 – 16 mm |

| Unladen weight | approx. 428 kg |

| Load capacity | 4’000 kg |

Trailer Carriage

The transport bar is available in two different lengths, 2.5 m and 3.5 m.

Advantages

- The trailer carriage is directly controlled from the carriage

- Increased safety through 2-fold hoisting when raising and lowering

- Increased safety during the run though locked load on the carriage and trailer carriage when the hook is completely retracted

- Higher load capacities – 5 tonnes for the trailer carriage with transport bar

- Long and heavy loads can be transported, lifted and lowered horizontally

FSI control sytem

The Wyssen’s own developed FSI control system is integrated in the HY-4 / HY-7 carriage. The control system is also mounted in the HY-2 carriage.

Advantages

- operable with radio

- Conventional timer switch possible (without radio signal)

- automatically switches off when not in use

- Erroneous clamping after passing a support is prevented

- clamping with a radio signal during the journey via set speed no longer possible

- Automatic emergency stop if the programmed speed limit is exceeded

- All parameters can be individually adjusted (speed, clamping and delay times)

- depending on the mode set, it is also possible to start/stop the diesel engine or rewind the haul-back cable

- protected against clamping if the battery is discharged

- Battery status display

- Resistant against moisture, vibration and impact due to completely enclosed electronics

- Software updates with improvements and upgrading are possible at any time, latest micro-computer control system